Monorail mine locomotive BEVEX 80

APPLICATION

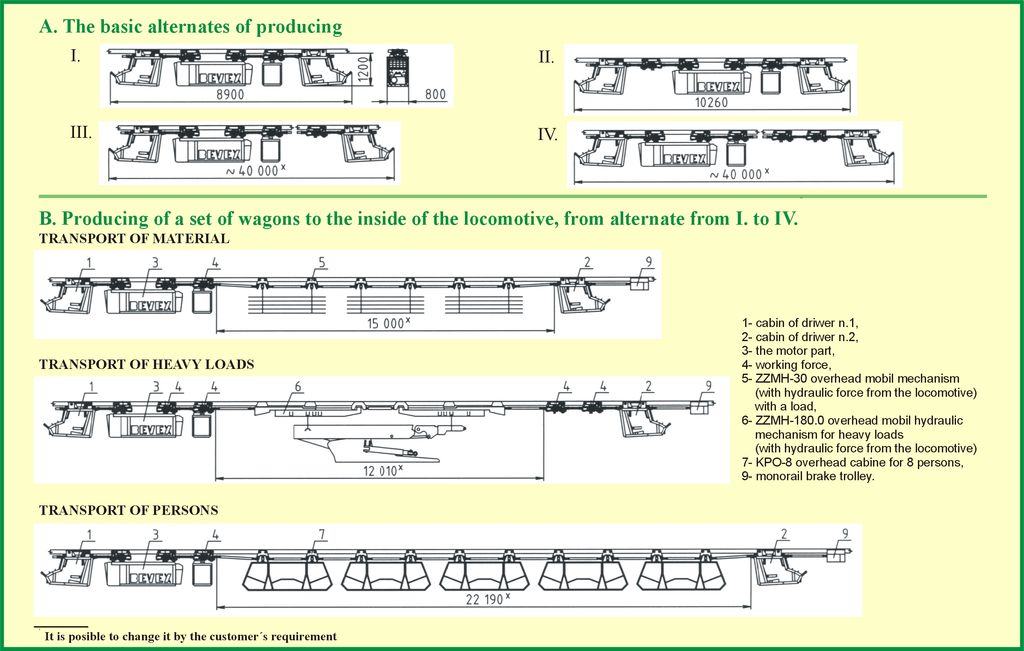

The BEVEX 80 monorail locomotive is designed for a set of wagons to be transported (men or materials) along an overhead monorail (I 155, I 250) of the written type (ZD-155, ZD-24, Pioma etc.) in the horizontal and inclined workings as well as on the surface up to 25° incline. It can be used in an explosion hazard enviroment in gates with an air flow of min. 330 m3.min-1. Four basic locomotive assemblies can vary in the operation (picture A). It´s possible to give the set of wagons between cabin number two and the motor part, with the transport material or cabin with people. It´s also determinated for transport the weghty burdens (picture B).

DESCRIPTION AND FUNCTION

The locomotive with the newest conception with the modern design has an electronic operating and the control by microcomputer, an incresed input. It consists of several units, and two cabins, the set type, the alternatives from I. to IV. (A). It provides the variability of connection with the set of wagons (B). Both, a driver and his assistant are present in the cabin. The drive is simple controlled with one level from the cabin facing the engine. Using the aplication with a set of wagons inside of the locomotive, the cabin is always

in the beginning of the train. It doesn´t turn at the station. It´s made with a longer join operating cable.

The locomotive is diesel-hydraulicpowered. The tractive force, transmitted on the driving pulleys (6, 8 or 10) is derived from the modern inflammable internal combustion engine through a hydrostatic transmission formed by the hydraulic generator and 6, 8 or 10 hydraulic motors. Driving adhesion is proportional to the momentary tractive force.

The locomotive is equipped with:

- electronic operation,

- an aic power regulation of the hydrostatic transmission,

- two brake systems,

- speed-limit devices,

- control transdecers for correct function with an optoelectronic signalling,

- an auxiliary circuit for feeding of the overhead mobile lifting mechanisms,

- black box.

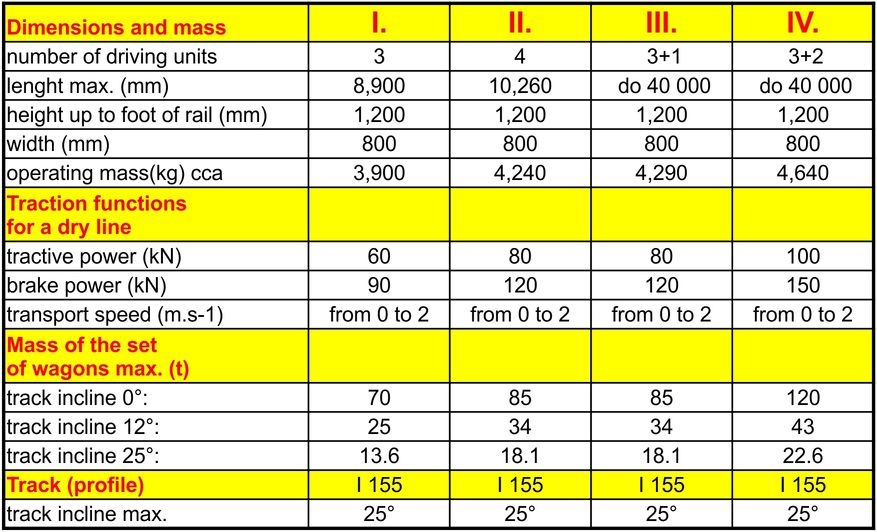

SPECIFICATIONS

Power

engine internal combustion type - input (turns) x 82 kW (40,0.s-1)

gear - hydrostatic, max. pressure 32 ÷ 35 MPa

CO content in exhaust gases - 0,05 %

NOx - 0,075 %

Auxiliary circuit (for feeding of the overhead mobile lifting mechanisms)

- circuit pressure max.. 20 MPa

Electrocircuit

- the main / operating and control 12 V ExiM2EExdI / 12 V; 5 V ExiM2EExibI

radius of curves - horizontal / vertikal 4 m / 8 m

ACCESSORIES

1. Basic:

- spare parts for one - years operation

- technical dokumentation

- service book

2. Special (on an individual order):

- a jig for testing of the PKO-1speed limit device,

- the jig for testing of tractive and braking power PMTS-120,

- the AS-16 starting aggregate,

- the hand pump of fuel and oil ČNO-2,

- the hand HA-9 hydr. aggregate.

Producer provides the high quality, working ability, quarantee and after quarantee service.